Governance and Innovation / Innovation Momentum

Innovation Momentum

Product Quality

WNC Quality Policy

On-time delivery of defect-free and competitive products & services to our customers

WNC has a “zero defects” long-term quality management objective. We seek to demonstrate our dedication to excellence in terms of design quality, product quality, and service quality. We not only strive to fully meet customer requirements, but also aim to build long-term, stable, and trustworthy partnerships, and become a benchmark in the industry.

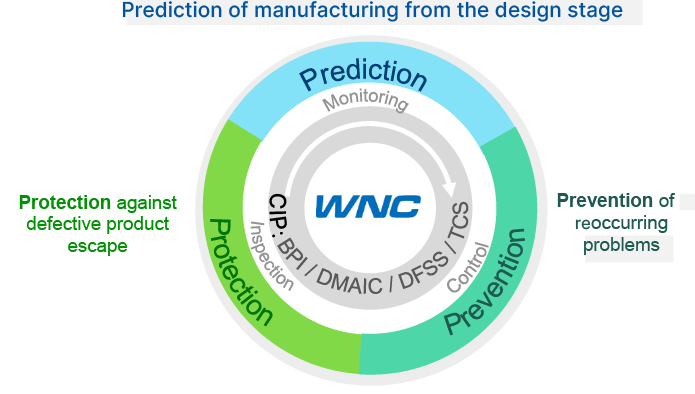

During our day-to-day quality operations, we strictly adhere to international management system standards for product categories based on ISO 9001, IATF 16949, TL 9000, and ISO 13485, while flexibly adjusting operational strategies as needed. We conduct annual reviews and set quality objectives covering three key areas: quality, service, and delivery. Through a top-down organizational implementation mechanism, we embed a quality mindset into every department and position. In the spirit of “Prediction, Prevention, and Protection”, different quality approaches, tools, and systems are introduced for integration with the product development process to build a high-performance quality management system that is realized in daily operations.

WNC (Taiwan) and WNC’s sites in China and Vietnam have all obtained ANSI/ESD S20.20 Electronic Discharge Control Program certification to ensure that comprehensive electrostatic protection measures are in place throughout the entire manufacturing process to safeguard product stability and reliability. The QE lab in WNC headquarters has also obtained ISO/IEC 17025 (general requirements for the competence of testing and calibration laboratories) certification. This not only highlights that WNC’s own laboratories adopt robust testing techniques and management capabilities, but also provides customers with highly accurate and efficient product testing and verification services, laying a solid foundation for high-quality products.

All WNC production sites implement Continuous Improvement Process (CIP), including Business Process Improvement (BPI), Total Customer Satisfaction (TCS) for manufacturing operations, Design for Six Sigma (DFSS) for R&D and WE (Waste Elimination). These initiatives involve analysis and evaluation to anticipate, identify, assess, and control potential risks, while simultaneously enhancing quality, design, cost, and efficiency across all operational levels, thereby building a solid and highly efficient operating environment. To encourage employees’ active participation in continuous improvement programs, a proposal-based improvement reward system has been established. In 2024, a total of 433 CIP proposals from Taiwan, China, and Vietnam sites received cash rewards, totaling approximately NT$888,880.

Intellectual Property

As of the end of 2024, WNC held 2,492 patents: 690 in the U.S., 1048 in Taiwan, 653 in China, and 101 in other countries. WNC continues to hold the number one ranking for patents granted to network communications companies, as listed by the Taiwan Intellectual Property Office in their Top 100 Domestic Patent Applicants rankings list, and has also received domestic and international awards numerous times, including the 2024 Hsinchu Science Park Innovative Product Award, and the 2024 National Invention and Creation Awards organized by Taiwan’s Intellectual Property Office.