Governance and Innovation / Supplier Management

Supplier Management

WNC Global Supply Chain Management Policy

Policy

Through continuous optimization of supplier management strategies and operational efficiency, WNC works with suppliers to manage sustainable supply chains. We aim to achieve balanced development among profitability, environmental protection and social responsibility, in order to create better value for all stakeholders.

Mission

By supporting the Company’s business development and enhancing the Company’s market competitiveness, WNC will continue to effectively manage and jointly improve the quality, price, delivery, service, and environmental and social responsibility performance of suppliers, and develop the most suitable supplier portfolio and purchasing policies to be able to work with suppliers in a responsible supply chain.

The materials and components WNC purchases are mainly integrated circuits, circuit boards, display panels, electromechanical components, mechanical parts, and packaging materials. Production consumables are mainly solder paste and solder wires used in manufacturing processes. In 2024, there were 1,015 qualified suppliers of raw materials, components, and manufacturing consumables to WNC’s sites. Among them, 491 are tier-1 or critical suppliers.

Local Procurement

Local procurement can support the development of local economies, generate employment opportunities and income, and reduce costs and carbon emissions of transportation. Therefore, WNC establishes a dedicated procurement team for each country/region, responsible for the selection and management of local suppliers. According to the amount of raw materials, components and production consumables purchased by WNC, suppliers in Taiwan are the main suppliers, accounting for 45% in 2024. Other suppliers are located in Asia, Europe and the United States.

Guidelines

In response to SDG 16, WNC requires all suppliers to sign a Supplier Commitment to Sustainability Declaration and a Supplier Integrity Commitment Letter, pledging to comply with the WNC Supplier Code of Conduct, which declares that they are committed to prohibiting the use of child labor, forced labor, and implementing occupational safety and health management, anti-bribery and anti-corruption measures, fair trade, and supporting freedom of association for workers and labor-management agreement rights. Suppliers are asked to complete a Supplier ESG Questionnaire so WNC can understand suppliers’ implementation of labor, health and safety, environmental, ethics, and management systems.

Suppliers can upload a Supplier Commitment to Sustainability Declaration, WNC Supplier ESG Questionnaire, Integrity Commitment Letter, and Legal Compliance Commitment Letter via Digital Supply Chain Portal (DSCP), in order to strengthen supply chain collaboration and improve efficiency, strengthen supply chain collaboration and improve efficiency. As of the end of 2024, 479 Tier-1 Suppliers and 328 Critical Suppliers have signed the Supplier Commitment to Sustainability Declaration and the Supplier Integrity Commitment Letter, accounting for 97.5% and 66.8% of all Tier-1 and Critical Suppliers respectively. Additionally, 484 suppliers have responded to the Supplier ESG Questionnaire, representing 98.57% of all Tier-1 and Critical Suppliers.

Risk Assessment

Starting in 2023, WNC adopted EcoVadis to assess the sustainability risks of its suppliers (alternatively accepting evaluation results from RBA, S&P Global CSA, or Sustainalytics). The initiative was first implemented with 100 key suppliers, incorporating their EcoVadis ratings – or equivalent scores from the aforementioned assessments – into the supplier performance evaluation process. In 2024, the program was expanded to cover all tier-1 suppliers, resulting in a total of 349 suppliers completing the sustainability risk assessment. To improve sustainable supply chain management, WNC offers periodic sustainable procurement courses for employees in the Global Supply Chain Management Division. These courses are also included as mandatory training for new procurement employees. Through sharing of trends in sustainable procurement and case studies, WNC hopes to implement the concept of sustainable procurement in materials procurement and the screening and management of suppliers. In 2024, all procurement employees completed the training.

WNC also communicates sustainable supply chain requirements to suppliers through the DSCP Supply Chain Platform and provides online Supplier Code of Conduct and anti-corruption training courses for suppliers. As of the end of 2024, all Tier-1 suppliers have completed the online courses.

Regular Audit

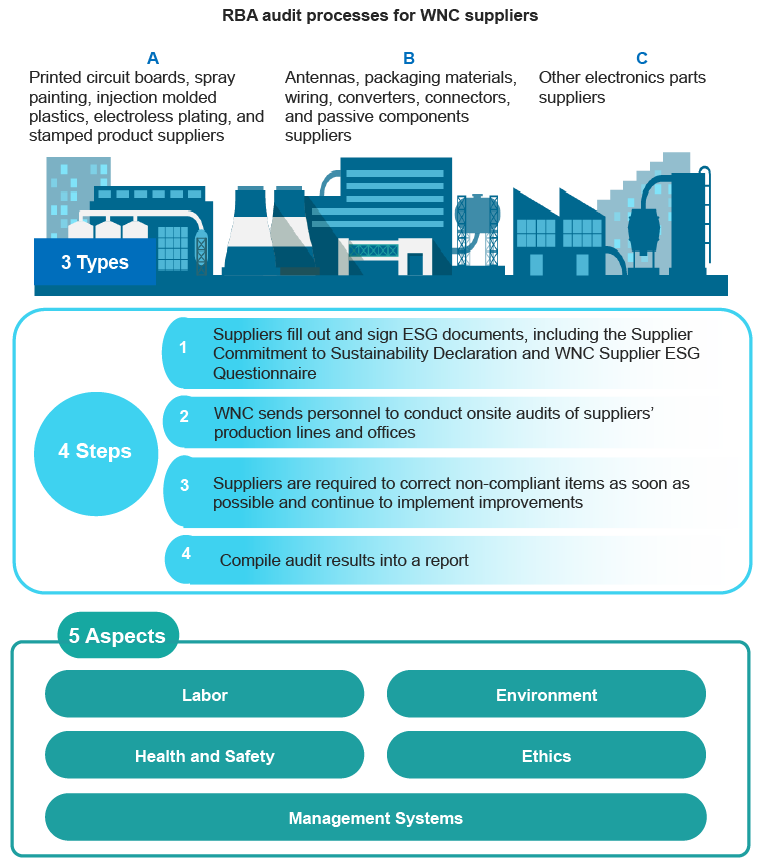

RBA Audit

A total of 50 Tier-1 Suppliers are scheduled to undergo WNC RBA audits annually. In 2024, the actual number of audits completed was 56, including 25 suppliers from Type A, 20 from Type B, and 11 from Type C. The non-compliant items in the audit results are mostly labor-oriented, health-oriented and safety-oriented, and environment-oriented. Examples include a lack of policies or procedures related to child labor, overtime work, inadequate lactation environment or facilities, blocked emergency exits, or insufficient firefighting equipment, failure to track energy consumption and greenhouse gas emissions, and absence of a waste management process.

All suppliers with identified non-compliant items agreed to implement corresponding improvement plans, which are tracked by WNC’s Supplier Quality Management Center. The suppliers work with the Global Supply Chain Management Division to follow the Supplier Evaluation Management Guidelines to supervise suppliers’ implementation of RBA specifications and continuous improvement. In 2024, no supplier relationships were terminated because the supplier’s RBA audit results or improvements did not meet the standards. In 2025, a total of 50 suppliers are scheduled to undergo an RBA audit.

Annual Audits and Counseling

Tier-1 Suppliers, Critical Suppliers or suppliers required to meet customer demands are selected for product quality, safety production, and RBA on-site audits annually. For suppliers whose audit results do not meet the required standards, specialists are assigned to review and formulate improvement plans, while providing appropriate assistance, counseling and training. In 2024, a total of 457 on-site audits and counseling sessions for supplier sites were arranged. These included 148 quality system audits, 195 product process audits, 58 Continuous Improvement Program sessions, and 56 RBA audits, covering 120 suppliers in total, with the RBA audits specifically involving 56 of those suppliers on-compliance items found during the audits include unclear definitions of specifications/procedures, deviations from SOPs for in-factory operations, and anomalies in record sheets. All identified issues have been remediated and resolved. None of the suppliers were required to terminate cooperation with WNC due to non-compliance items found during audits or unsatisfactory results after remediation.

Quarterly Reviews

WNC has established a Supplier Performance Review Committee with personnel from the Global Supply Chain Center, Supplier Quality Management Center, and R&D Projects unit. Comprehensive performance evaluations are conducted based on supply chain performance indicators on a quarterly basis.

WNC conducts a quarterly Vendor Performance Evaluation (VPE), with key evaluation criteria including quality, delivery, service, and price competitiveness. To strengthen supply chain sustainability and resilience, a 5% bonus was introduced in 2024 for suppliers with sustainability risk ratings, encouraging them to advance ESG initiatives. Additionally, sustainability risk ratings are being progressively incorporated into the formal performance evaluations for key suppliers, accounting for 10% of the total score. For suppliers with higher sustainability risk ratings, the Supplier Quality Management unit will conduct subsequent audits and follow up on corrective actions.

After completing the quarterly Vendor Performance Evaluation (VPE), the Global Supply Chain Center will, based on the VPE results and strategic considerations, work with the Supplier Quality Management Center, R&D project and mechanical design units etc. to compile a Recommended Vendor List (RVL) for the selection of new partners and purchasing targets during the recommended supplier meeting each quarter.

Supplier Partnership

WNC signed the SBTi Commitment Letter and committed to achieving net-zero emissions by 2050, aiming to drive our suppliers to create a low-carbon supply chain together. Therefore, WNC has held a Sustainable Supplier Conference from 2023 and engages in dialogue on related topics with supply chain partners. In 2024, WNC held two supplier conferences, inviting a total of 155 domestic and international suppliers, including 99 key suppliers and 56 suppliers with potentially high carbon emissions to participate. In addition to sharing WNC’s sustainability strategy and carbon management requirements for suppliers, industry experts were invited to deliver training sessions on “Global Sustainability Trends”, “Carbon Inventory/Carbon Footprinting”, and “Biodiversity”. Overall satisfaction rating of 4.91 points (out of 5). To strengthen collaboration with overseas suppliers and enhance the overall sustainability resilience of the supply chain, WNC held two Sustainable Supplier Conferences in Vietnam in March 2025. These conferences aimed to communicate WNC’s sustainable supplier strategies and requirements, and to provide carbon management training to enhance the knowledge and capabilities of suppliers in the Vietnam region in carbon reduction.

WNC also invites its suppliers to participate in the annual Wistron Group Vendor Conference. During the event, WNC commends suppliers who have performed outstandingly or made special contributions. In 2024, 103 WNC suppliers attended the Wistron Group Vendor Conference.

Responsible Minerals

WNC has formulated the Responsible Minerals Policy Statement, committed to banning the use of conflict minerals that contribute to significant human rights violations such as armed conflict and forced labor in conflict-affected and high-risk areas (CAHRAs). Suppliers are required to avoid using conflict minerals, disclose the sources of tin (Sn), tungsten (W), tantalum (Ta) and gold (Au) they use and communicate this policy to their upper stream suppliers to achieve alignment throughout the supply chain.

WNC conducts supplier conflict mineral surveys via the CMRT to find out whether smelters used by suppliers are participants in the Responsible Minerals Assurance Process (RMAP). WNC requires new suppliers who use conflict minerals in their products to provide valid supporting data regarding the necessity of using conflict minerals as well as corresponding investigation and management mechanisms for said minerals. In addition, WNC requires suppliers to promise that products they provide to WNC do not violate WNC’s Responsible Minerals Policy Statement by signing a Supplier Quality Agreement, and also requires that suppliers do not conduct business with smelters that are confirmed to have contributed to human rights violations.

According to survey results in 2024, there are a total of 197 smelters within WNC’s supply chain, of which 195 are RMAP-compliant smelters, accounting for 99.0% of the total. Two are participating in the RMAP program. WNC will continue to monitor the compliance status of these two smelters to ensure that products delivered to customers meet their conflict minerals requirements.